Description:

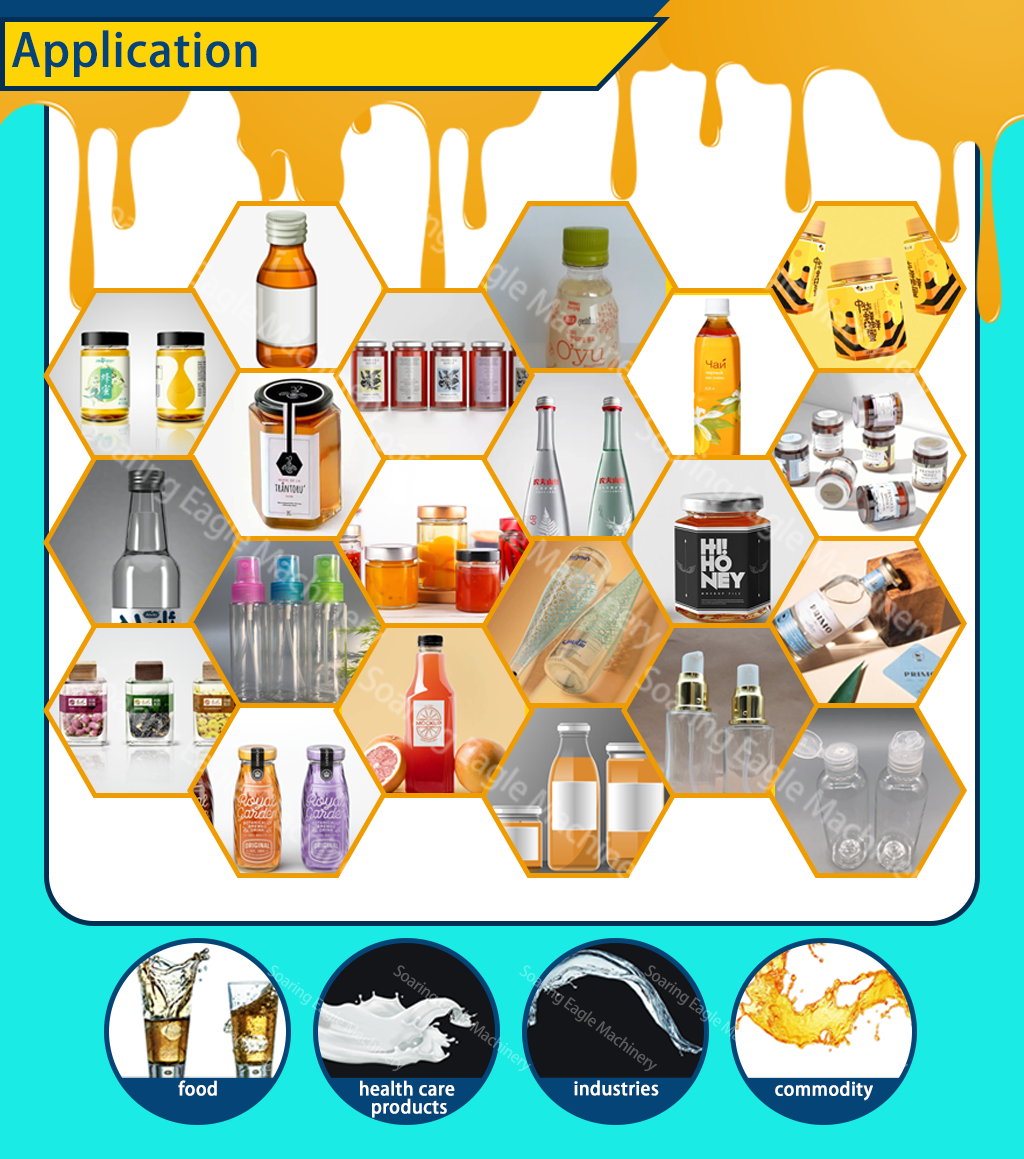

The fully automatic liquid bottle filling machine could filling different product according to customer requirements. Most consumers use this packing machine to pack cosmetic, daily product, pesticide, pharmaceutical, shampoo, perfume etc liquid and cream. The bottle filling machine has another name, which called full automatically filling and capping machine, widely used in bottle liquid filling and capping. You could choose different filling nozzles, such as four dozes, six dozes. Different customers have different speed requirements. The automatic machine improve producing time. With the rapid development of the national economy, the bottle filling machine function has highly improved. It uses Siemens PLC and touching screen, the machine is more stable than the normal machine. It could also be connected with other machines, for example weighting machine, labeling machine, capping machine,bottle feeding machine and so on.

We could design the machine position depending on your factory. It is for free. Our machine is OEM & ODM design. The high quality machines make you feel at ease.

Technical parameter:

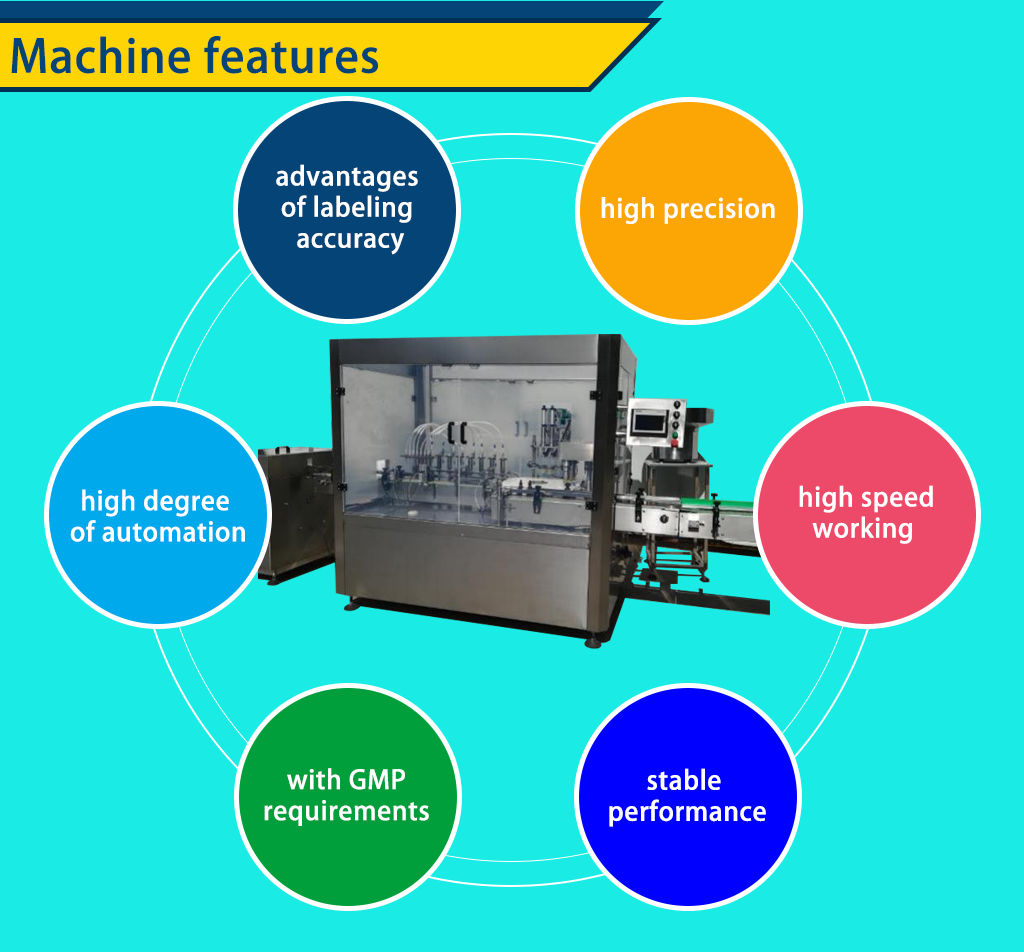

1. PLC control system, color touch screen display.

2. Machine has sensor to control function of no bottle no filling, lack bottle no filling.

3. With servo motor control piston pump, customer could adjust filling volume on touch screen directly.

4. Working process: bottle unscrambling(optional)--filling--adding spray pump--screw capping--adding outer cap on bottle

-- labeling (option)--coding (option).

5. Machine is compact, high speed, high performance and high degree of automation.

6. With(glass) safety cover, avoid hand hurting by machine during machine working.

7. Machine body and product touching part are made by304 stainless steel,

8. It completely meets GMP requirements.

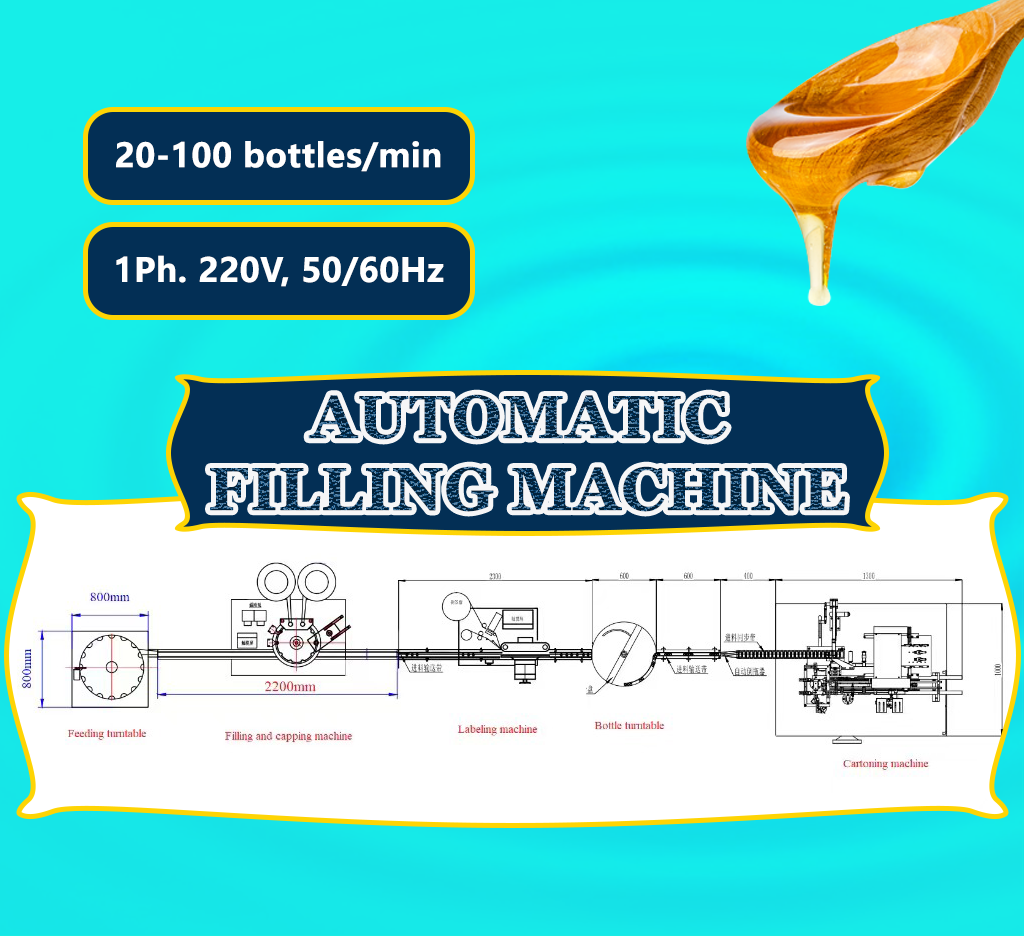

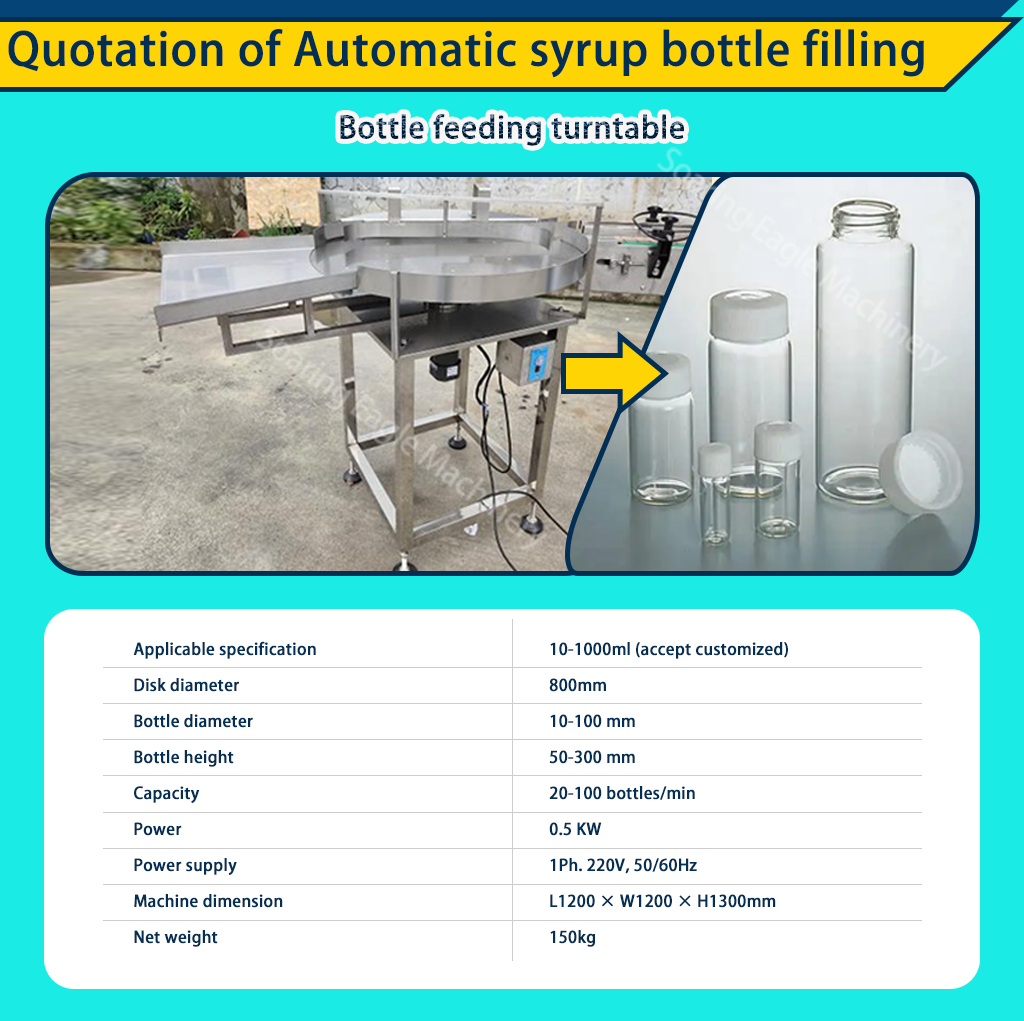

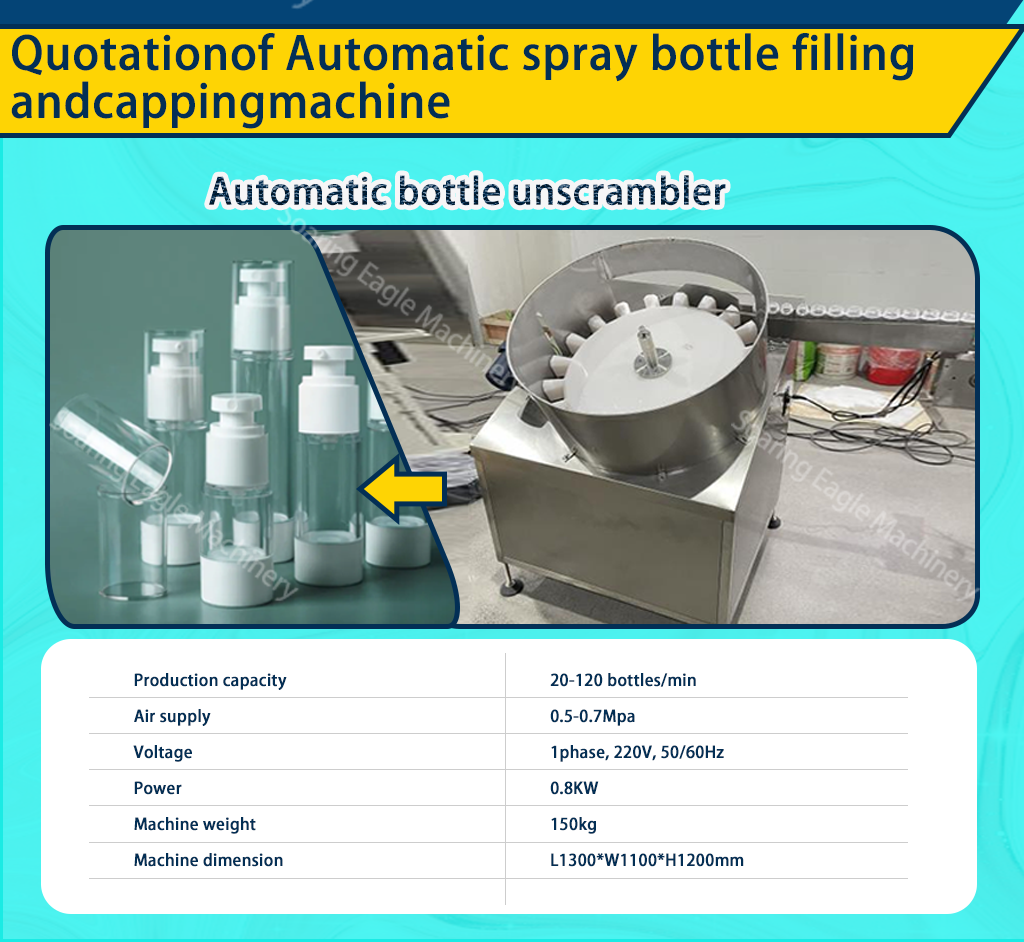

Specifications:

| Model : | Bottle feeding turntable |

| Applicable Specification : | 10-1000ml(accept customized) |

| Disk Diameter : | 80mm |

| Bottle Diameter: | 10-100mm |

| Bottle Height : | 50-300mm |

| Capacity : | 20-100 bottles/min |

| Power : | 0.5KW |

| Power Supply: | 1Ph, 220V, 50/60Hz |

| Machine Dimension: | L1200*W1200*H1300mm |

| Net Weight: | 150kg |

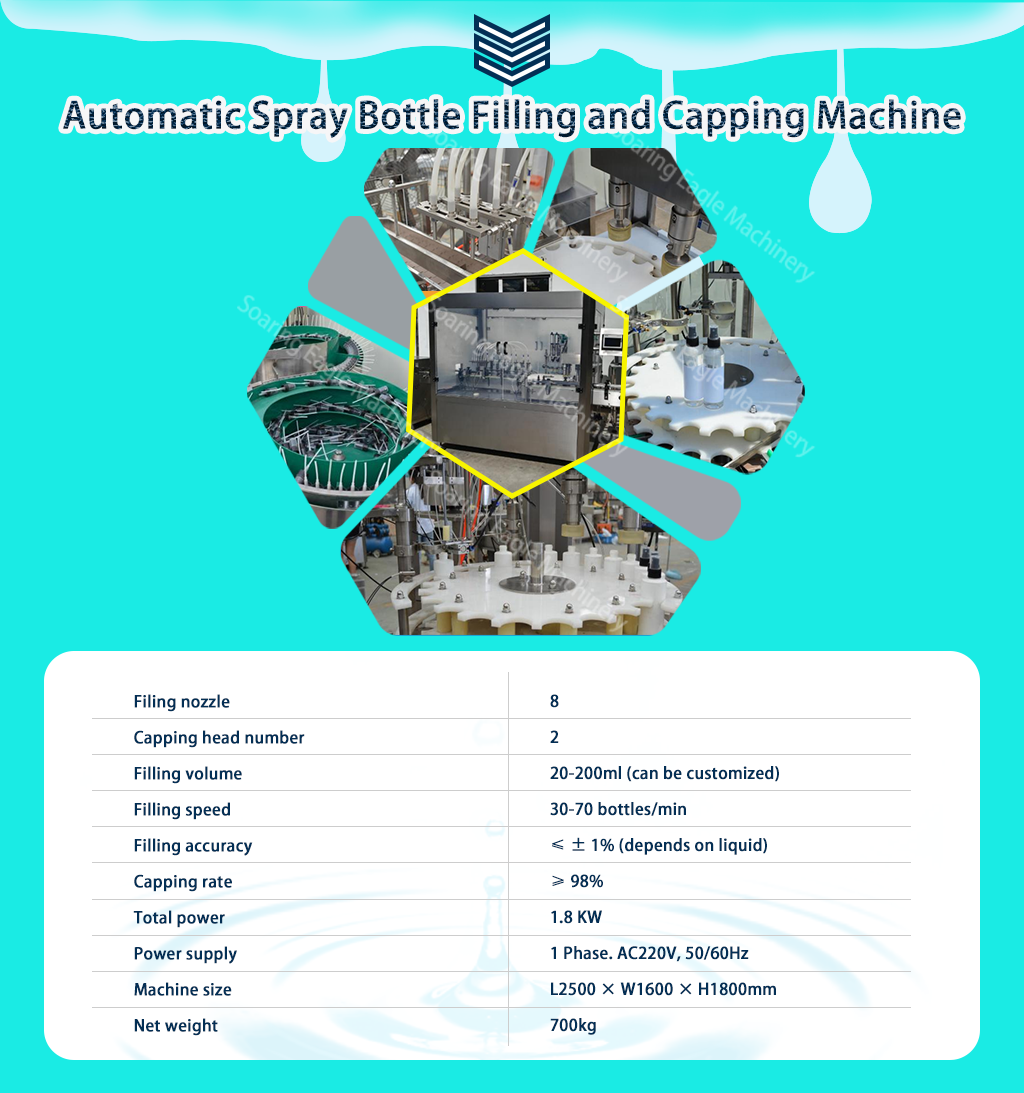

| Model : | Liquid filling and capping machine |

| Filling nozzle number : | 6 |

| Capping head : | 1 |

| Filling Volume : | 120ml,240ml |

| Filling Accuracy : | ≤1% |

| Production Capacity : | 20-30 bottles |

| Air Supply : | 1.5m3/h, 0.4-0.7Mpa |

| Voltage: | 220V, 50/60Hz |

| Power Supply: | 2.5KW |

| Machine Net Weight: | 700kg |

| Machine Dimension | L2800*W1500*H1900mm |

| Model : | Automatic bottle labeling machine |

| Production Capacity : | 30-120 bottles/min |

| Labeling Accuracy : | ≤0.3mm |

| Label Length : | 10-180mm |

| Label Height : | 10-150mm |

| Power | 1.5KW |

| Power Supply: | 1Phase, 220V, 50/60Hz |

| Weight: | 200kg |

| Machine Dimension | L2200*W1200*H1350mm |

Our friendly team would love to hear from you!